+86-15726853660 / +86-18301913645

+86-15726853660 / +86-18301913645

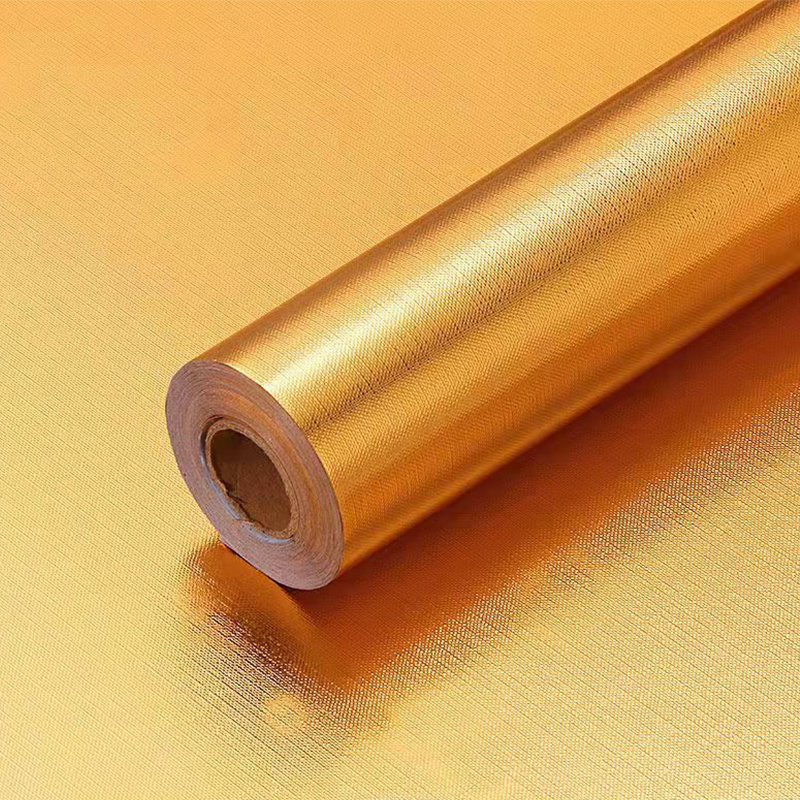

PVC Decorative Film is a flexible surface material made from polyvinyl chloride, designed for decoration and surface protection. It is produced through printing and coating processes that allow it to imitate wood grain, stone textures, solid colors, or functional finishes. In interior and commercial environments, PVC Decorative Film is widely used to upgrade surfaces without structural replacement.

This material is commonly applied to MDF boards, plywood, metal panels, furniture surfaces, doors, cabinets, and wall panels. Compared with traditional surface treatments, it offers a stable appearance, performance, and consistent texture across large areas. As a result, many projects rely on PVC Decorative Film to maintain visual continuity in kitchens, offices, retail spaces, and residential interiors.

From an industry perspective, a qualified PVC Decorative Film Manufacturer focuses on coating stability, pattern clarity, and dimensional control. These factors affect how the film performs during lamination, wrapping, and long-term use.

PVC Decorative Film supports both decorative and functional uses across different environments. Application scenarios vary depending on film structure and surface coating.

Typical application areas include:

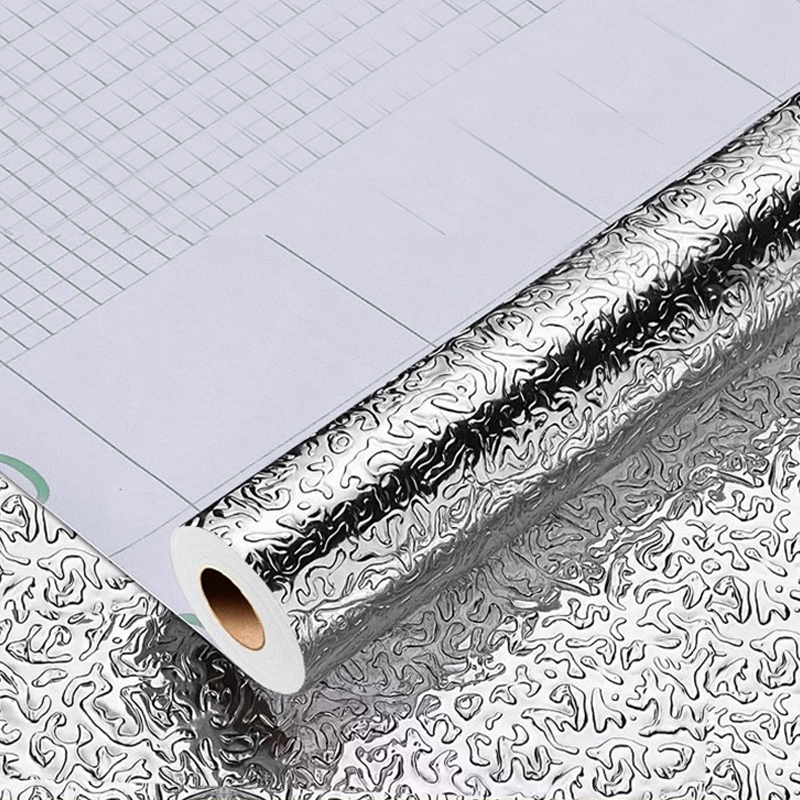

Within specialized product lines, films may provide additional functions. For example, metal surface oil-proof wallpaper helps reduce grease stains in cooking areas, while double-sided transparent furniture protection film protects surfaces without changing their appearance. Aquarium decorative film is used for visual backgrounds, and heat insulation film helps manage indoor temperature and glare.

A PVC Decorative Film Manufacturer usually develops these variants to match real installation conditions rather than abstract design concepts.

Installation quality depends on surface preparation and handling techniques. PVC Decorative Film is designed to adapt to flat and slightly curved substrates when applied correctly.

Common installation steps include:

Balanced thickness and controlled shrinkage help the film remain stable after bonding. For workshops and project sites, predictable installation behavior reduces rework and material waste. This is why experienced fabricators often evaluate not only appearance but also processing compatibility when selecting products from a PVC Decorative Film Manufacturer.

PVC Decorative Film naturally forms a moisture-resistant layer due to its PVC structure. This makes it suitable for areas where humidity or occasional water exposure is common.

Key performance characteristics include:

Some films also include surface coatings that resist household oils and mild cleaning agents. These features are developed during formulation and coating stages by the PVC Decorative Film Manufacturer, based on usage feedback from interior and commercial projects.

Working directly with a PVC Decorative Film Manufacturer allows better control over material consistency, pattern matching, and technical specifications. Manufacturers manage the entire process, from PVC formulation and printing to coating and slitting.

From an industry standpoint, this approach supports:

A manufacturer-focused supply model also supports long-term project planning, where consistency across different phases matters. For surface material industries, PVC Decorative Film remains a practical option that combines decoration and surface protection in one solution.

By combining functional design with adaptable application, PVC Decorative Film continues to play an active role in modern surface finishing. When developed and supplied by an experienced PVC Decorative Film Manufacturer, it fits smoothly into furniture, interior, and commercial material systems without complicating installation or maintenance.

+86-15726853660 / +86-18301913645

No. 99, Jinxiang Road, Hubin New District, Suyu, Suqian City, Jiangsu Province, China