+86-15726853660 / +86-18301913645

+86-15726853660 / +86-18301913645

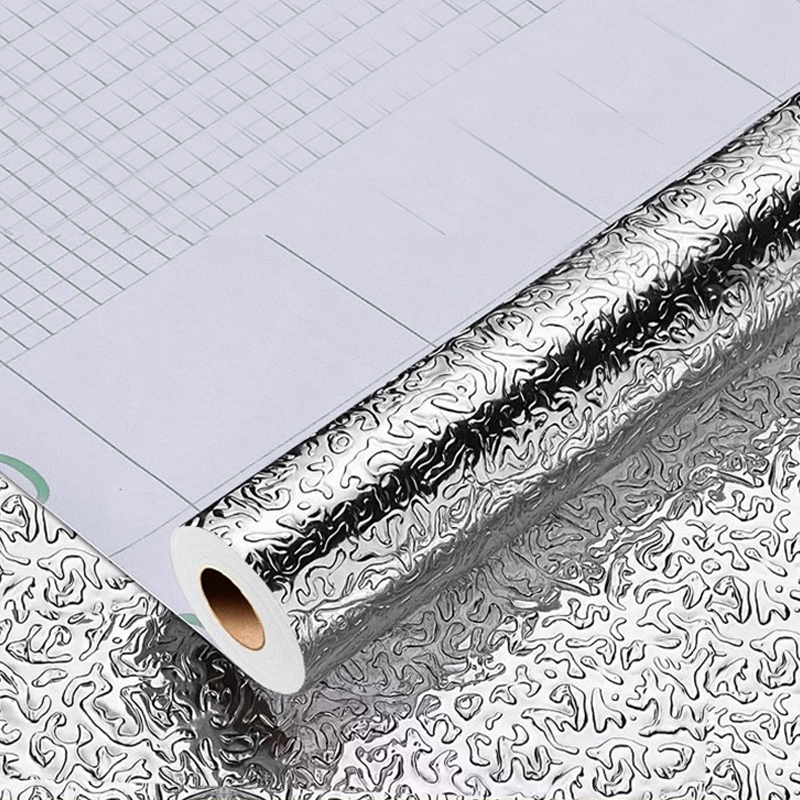

PVC Decorative Film is used in many interior projects where buyers want new looks without heavy renovation work. It is a thin PVC-based surface film with printed designs such as wood grain, stone, solid colors, or custom patterns. Many industries choose it because it gives surfaces a fresh appearance while staying practical for daily use. A PVC Decorative Film Factory works closely with furniture producers, distributors, and contractors who need a stable supply, flexible designs, and film that performs well after installation.

The material often appears on cabinet panels, wardrobe surfaces, doors, furniture boards, and interior walls. Because it stays light and flexible, it works with MDF, plywood, metal sheets, and similar substrates. Below are points that answer common questions raised by buyers looking for dependable surface solutions.

Users want surface materials that look good and function well for long periods. PVC Decorative Film offers consistent color and pattern control, which is helpful when covering large areas or matching multiple panels. Digital printing captures the fine details of wood and stone while providing a smooth and uniform finish.

For homes, the film helps refresh outdated kitchen cabinets or storage furniture without replacing the structure. Commercial projects use it for wall panels or store fixtures to keep a brand's visual style unified. Because the film is light, it reduces transport and handling effort, which matters for bulk buyers.

Customers often ask how the film reacts in humid or warm environments. PVC Decorative Film has good moisture resistance due to its PVC layer. It does not absorb water, so the surface remains stable in bathrooms and basements. This helps reduce peeling or swelling, issues often seen with natural veneers.

In kitchens, the film handles normal cooking heat and light splashes. It stays easy to clean because the protective layer resists oils and common stains. Many buyers use it for side panels, cabinet faces, and decorative wall sections instead of heavy materials like real wood or stone.

When exposed to sunlight, UV-stable additives help maintain color over time. The protective coating also supports scratch resistance, which is important for high-touch furniture surfaces.

Installation matters for both small home projects and large commercial sites. Smooth application depends on clean preparation and proper bonding. The film works well with wood-based boards and metal surfaces when applied with suitable adhesives.

Users can work through the application using a squeegee to remove air pockets, which helps avoid bubbles. A heat gun assists when wrapping curved edges. With the right steps, the film settles firmly, reducing future lifting or shrinking. This makes it accessible for DIY users while still supporting professional results on large jobs.

A PVC Decorative Film Factory usually offers films with controlled shrinkage and balanced thickness to support easier installation and long-term stability.

Retailers, furniture brands, and renovation contractors often need consistent patterns and regular production. Working with a stable PVC Decorative Film Factory gives them predictable roll sizes, packaging options, and the ability to customize designs.

PVC Decorative Film allows designers, builders, and homeowners to refresh surfaces with flexible, attractive, and practical materials. It supports everyday use in kitchens, bathrooms, living spaces, and commercial interiors, while offering the customization and supply stability needed by businesses and distributors.

+86-15726853660 / +86-18301913645

No. 99, Jinxiang Road, Hubin New District, Suyu, Suqian City, Jiangsu Province, China