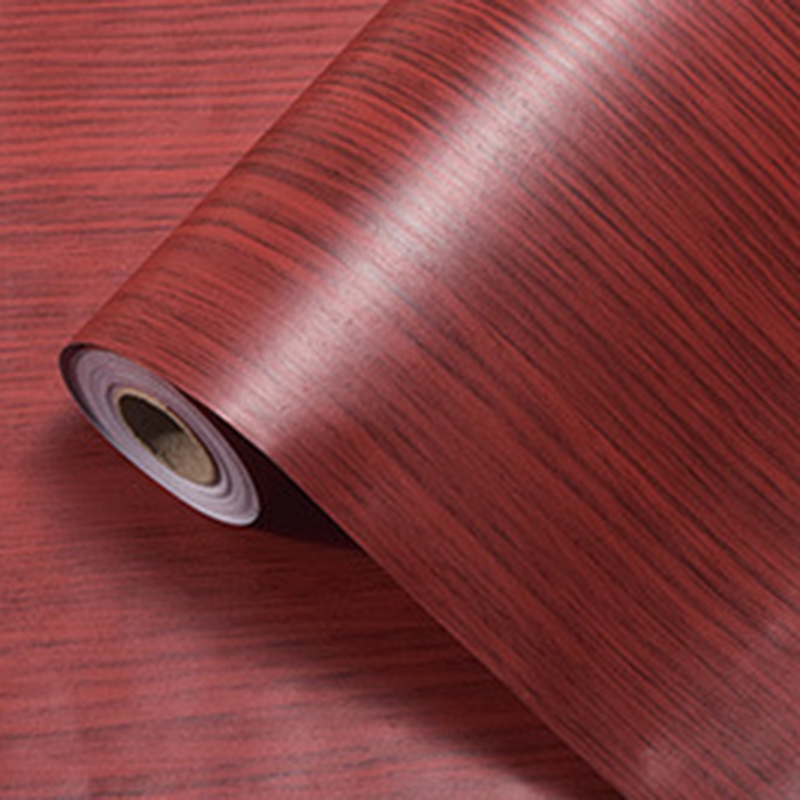

High Opacity Full Matte PVC Vinyl Film Industry Knowledge Extension

Applications of Full Matte PVC Film

- Signage and Graphics: Full Matte PVC film is ideal for outdoor and indoor signage due to its durability and resistance to UV rays. It ensures that the colors remain vibrant for a longer period without fading.

- Vehicle Wraps: It's widely used for vehicle wraps because of its conformability and ability to adhere to curved surfaces without showing the underlying shine.

- Window Decals: Matte PVC film is good for window decals as it offers a non-reflective finish, allowing for clear visibility through the window while maintaining privacy.

- Exhibition Stands: For trade shows and exhibitions, matte PVC film provides a professional and sleek look to display stands and promotional materials.

- Packaging: In the packaging industry, full matte PVC film is used for creating a high-end appearance for products, enhancing their market appeal.

Advantages of Full Matte PVC Film

- Durability: Our full matte PVC film is designed to withstand various weather conditions, making it a durable choice for long-term applications.

- UV Resistance: It comes with a protective layer that resists ultraviolet light, ensuring the colors do not fade quickly.

- Scratches Resistance: Our film is scratch-resistant, which is crucial for maintaining the appearance of the graphics over time.

- Eco-Friendly: We pride ourselves on producing eco-friendly products that are recyclable, reducing environmental impact.

Matte Plastic Film vs. Glossy Plastic Film

1. Surface Finish: Matte plastic film has a non-reflective, flat finish, which reduces glare and provides a more sophisticated look compared to glossy plastic film, which has a shiny, reflective surface.

2. Color Perception: Matte films can provide a more accurate color representation as they do not reflect light, which can alter the perception of colors in glossy films.

3. Application Suitability: Matte films are often preferred for applications where a professional, non-glare finish is required, such as in offices or high-end retail settings, whereas glossy films are used for applications that require a high shine and vibrant colors, such as automotive finishes or product packaging.

4. Printing Compatibility: Matte films can be more challenging to print on due to their non-reflective nature, requiring specific inks and printers that are compatible with matte surfaces. Glossy films, on the other hand, are more forgiving and can take a wider range of inks.

High Opacity Vinyl Film in Printing: Advantages

1. Opaque Coverage: High opacity vinyl film ensures that the colors are rich and vibrant, with no show-through from the underlying surfaces or colors.

2. Durability: This type of film is made to last, with a strong resistance to scratches, tears, and fading, making it ideal for long-term outdoor applications.

3. Flexibility: High opacity vinyl films are flexible, allowing for easy application on complex surfaces without the risk of cracking or peeling.

4. Weather Resistance: It is designed to withstand various weather conditions, maintaining its appearance over time.

5. Cost-Effective: While high opacity vinyl film may have a higher upfront cost, its durability and longevity make it a cost-effective choice in the long run.

Thickness Options for Matte Plastic Film

1. Thinner Options (50-100 microns): These are ideal for short-term applications such as event decorations or temporary signage where a lightweight and easy-to-handle material is preferred.

2. Medium Thickness (100-200 microns): This range is good for general-purpose applications, providing a balance between durability and cost.

3. Thicker Options (200-300 microns): For heavy-duty applications, such as vehicle wraps or long-term outdoor signage, thicker matte plastic films offer increased durability and resistance to environmental factors.

4. Custom Thicknesses: As a manufacturer, we understand that every project has unique requirements. We can provide custom thickness options to meet specific project needs.

Operational Tips for Using Matte Plastic Film

1. Preparation: Ensure the surface to be applied is clean and free of dust or debris for adhesion.

2. Cutting: Use a sharp blade or a digital cutter for precise cuts to avoid frayed edges.

3. Application: Apply the film smoothly and evenly, using a squeegee to remove air bubbles and ensure a good finish.

4. Storage: Store matte plastic film in a cool, dry place to maintain its quality and prevent damage.

5. Maintenance: Clean the film regularly with a mild detergent to keep it looking new and extend its lifespan.

As a manufacturer, we offer matte PVC films in various thicknesses and opacities, committed to meeting the diverse needs of our customers.