Interior Decorative Film Industry Knowledge Extension

What is Interior Film?

Interior Film is a high-performance architectural surface material designed for interior decoration and renovation. It is made from durable PVC or PET-based layers, combined with an advanced adhesive backing that allows easy installation on various surfaces. Unlike paint or wallpaper, Interior Film offers a quick, clean, and efficient way to refresh walls, doors, furniture, and ceilings. It comes in a wide range of textures, such as wood grain, marble, metallic, fabric, and matte finishes, providing designers and contractors with versatile options for both residential and commercial environments.

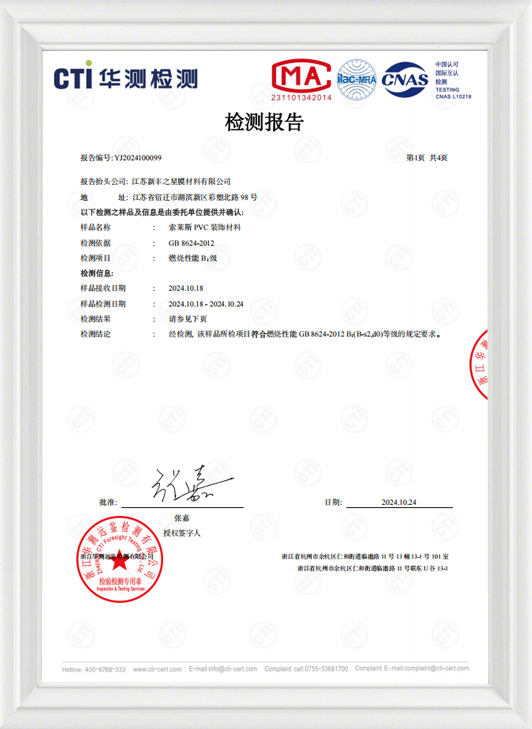

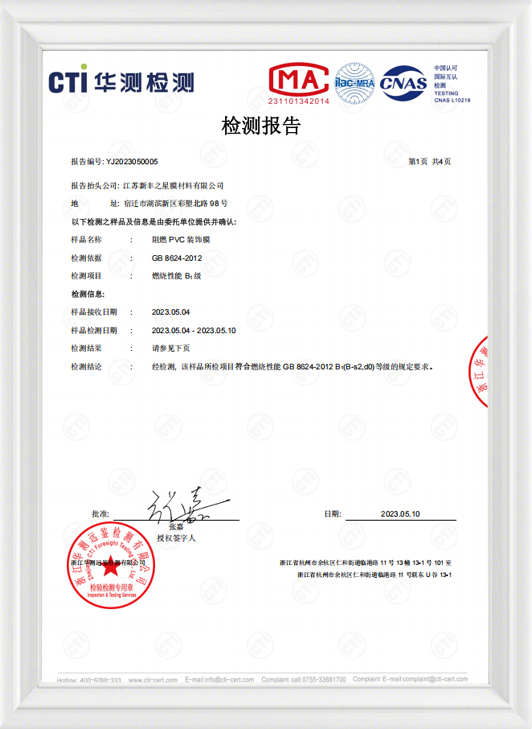

As a manufacturer, we focus on producing Interior Films with outstanding adhesion, heat resistance, and flexibility, ensuring they perform well even in high-traffic or high-humidity areas. Modern Interior Films are also eco-friendly—free from heavy metals and low in VOC emissions—making them safe for use in hospitals, hotels, offices, and homes.

How is Interior Film different from wallpaper?

While both materials are used for surface decoration, Interior Film and wallpaper differ significantly in structure, performance, and application methods.

Material Composition

Wallpaper is typically paper-based or vinyl-coated, which makes it thinner and more vulnerable to damage or moisture.

Interior Film, on the other hand, is made of multilayer vinyl or PET, giving it enhanced durability, water resistance, and longevity.

Application Surfaces

Wallpaper is suitable mostly for flat wall areas.

Interior Film can be applied to metal, wood, glass, MDF, aluminum, or plastic surfaces, making it ideal for refurbishing furniture, doors, cabinets, and even elevator interiors.

Installation Process

Wallpaper requires paste or water-activated glue and can be messy to install.

Interior Film features self-adhesive technology, enabling a cleaner, faster installation without additional adhesive. Many manufacturers provide films with air-release channels, preventing bubbles and wrinkles during application.

Durability and Maintenance

Wallpaper may peel or fade over time.

Interior Film is scratch-resistant, easy to clean, and designed to last for years even under daily wear and tear.

Interior Film outperforms wallpaper in professional-grade design projects where durability, flexibility, and visual realism are essential.

Is Interior Film removable or permanent?

As manufacturers, we understand the importance of both temporary and long-term solutions. Interior Films are designed to be semi-permanent—they adhere securely for years but can be removed without damaging the underlying surface if handled properly.

- Removable Advantage: Premium films use pressure-sensitive adhesives that allow repositioning during installation and easy removal when renovation or replacement is needed. This feature makes Interior Film ideal for retail stores, exhibition booths, and leased properties where frequent design updates are required.

- Permanent Bond: For high-durability applications like elevators, counters, or hotel walls, manufacturers can supply stronger adhesive grades that ensure the film stays bonded even in challenging environments.

When removing the film, using gentle heat from a heat gun helps soften the adhesive, allowing it to peel off smoothly. This versatility is one of the major advantages of choosing Interior Film over traditional materials.

Where can I apply Interior Film?

Interior Film's adaptability is one of its greatest strengths. From a manufacturer's view, we design our products to adhere firmly to alany smooth surface, making them suitable for a wide range of applications:

- Walls and Ceilings: good for creating modern interiors in homes, offices, and commercial buildings without heavy renovation work.

- Doors and Frames: Interior Film can transform old wooden or metal doors, giving them a fresh appearance with minimal downtime.

- Furniture and Cabinets: Ideal for resurfacing existing furniture, providing a cost-effective alternative to replacement.

- Retail and Hospitality Spaces: Used for quick refurbishments in hotels, showrooms, or cafes where visual aesthetics are critical.

- Elevators and Public Areas: Fire-retardant and durable grades of Interior Film are suitable for high-traffic and vertical applications.

Application Tips from Manufacturers:

- Ensure the surface is clean, dry, and free from dust or oil.

- Use a squeegee or air-release tool to eliminate bubbles.

- Apply light heat to conform the film to curved or 3D surfaces.

- Avoid applying on rough, porous, or uneven substrates for adhesion.